Plastics2chemicals: a breakthrough solution for end-of-life plastics

Today’s global market is facing an increasing demand for sustainable recycling solutions for plastics waste. Some years ago, Indaver invested in a development program named ‘Plastics2chemicals’ (P2C) to find a safe recycling process for postconsumer plastics for which there are no proper recycling possibilities available today. Because of the good progress of this process combined with the urgency in the market, Indaver has decided to speed up its P2C development and investment program.

Expertise in chemistry and sustainable waste management accelerate success of P2C development

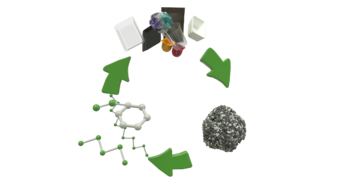

With its P2C installation Indaver wants to develop a safe and sustainable solution for postconsumer plastic waste. Years of research and development resulted in a depolymerisation process in which plastics are converted into high-grade recycled resources like styrene, naftha and waxes for the (petro)chemical industry. Indaver’s years of expertise in recycling waste right down to the molecular level, contributed and accelerated the positive outcome of the P2C project.

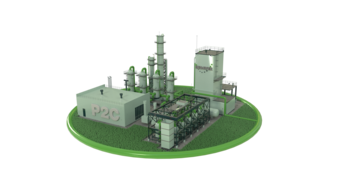

Test rig at university & permit application ongoing

The depolymerisation and purification process was tested intensively in cooperation with Flemish universities in which Indaver’s own test rig was used. Today the test rig has developed into a chemical mini factory. In parallel, Indaver is planning a demo-installation with a recycling capacity of 15.000 tonnes a year. In close consult with the relevant authorities, a permit application was submitted. The preparations are progressing well. Indaver expects to start construction of the P2C demoplant in 2022.

The demo installation will recycle waste from polystyrene as well as mixed polyoleofines. If all goes according to plan, Indaver will invest in a next step: building a dedicated polystyrene- and a dedicated polyolefines plastics recycling installation.

Cooperation with industry is crucial

Because high-quality recycled resources are used to replace the current primary resources, close cooperation with the chemical industry is essential. That is why Indaver works together with preferential partners, producers of styrene and polyolefine plastics to secure the offtake of the produced so-called ‘chemical feedstock’, resources for the industry.

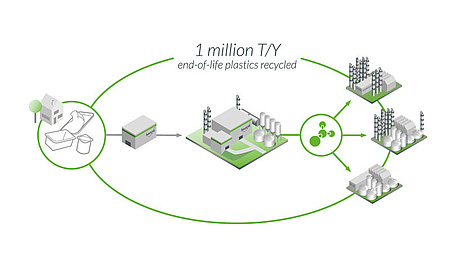

In total, Indaver is planning different facilities in Europe to eventually recycle 1 million tonnes of plastics.

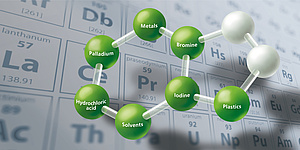

Indaver Molecule Management

Residual waste streams are increasingly seen as potential raw materials at a molecular level. As a company that handles around 5 million tons of waste products every year, Indaver knows what the valuable recoverable materials are. Our Indaver Molecule Management is intent on reintroducing materials from waste into the materials loop as much as possible. We examine the tiniest building-blocks – molecules – of the waste streams treated at Indaver to see which ones can be reused safely and effectively, with a quality that is no different from the original product.